Are You Still Doing Pressure Vessel Calcs by Hand? Here’s What It’s Costing You.

Are You Still Doing Pressure Vessel Calcs by Hand? Here’s What It’s Costing You.

If you are still building pressure-vessel calculations by hand or stitching them together in Excel, you are paying a tax you cannot see on schedule, quality and reputation. Every hour spent transcribing tables, eyeballing graphs, copying values between sheets or unpicking someone else’s formulas is an hour not spent on design intent, failure modes or scope. Reviewers feel this pain as much as engineers. RPEQs are routinely handed sprawling workbooks with hidden cells, legacy assumptions and no reliable way to trace which version produced the PDF on their desk. The problem is not that spreadsheets are always wrong; it is that you cannot quickly prove they are right. And this cost does not stop at nozzle, it affects routine calculations that make up every real projects.

Context: production plants carry high downtime costs—clarity and traceability reduce risk.

The Hidden Costs You’re Already Paying

Context: small frictions—transcription, rework and audit gaps—accumulate into delays and uncertainty.

Manual workflows rarely fail loudly; they leak time and certainty. The first leak is transcription. Engineers move between Code clauses, curve fits and internal check tables, re-typing or copy-pasting values. Even when every number is correct, the task consumes attention better spent on real engineering problem solving deilvers value. The second leak is rework. A late change to a nozzle load case or vessel thickness forces you to thread new numbers through a workbook built earlier for a different geometry. You spend valuable time reacquainting yourself with your own logic before you can safely adjust it. The third leak is review friction. A conscientious reviewer wants evidence that inputs, method and outputs are consistent and traceable. If the workbook does not surface assumptions, Code edition and calculation method on page one, the reviewer slows down and rebuilds trust from first principles. Multiplied across every calculation package in a job, the compounding effect becomes obvious.

Why Spreadsheets Fail in Engineering Contexts

Spreadsheets are powerful and familiar, but they are an undisciplined medium for safety-critical design work. In pressure-vessel practice, the same failure modes recur. Version drift is the most corrosive. Files are emailed, saved to network drives and cloned for similar jobs. Months later, few can say with confidence which workbook created the signed report, or whether it contains the late-stage change the client requested. Hard-coded cells are the quiet killer. A formula replaced with a value during troubleshooting becomes permanent. The spreadsheet still calculates, but the dependency chain is broken and future edits no longer propagate as intended. Unit errors creep in as a single kN entered as N slips through unchallenged. Copy-and-paste mistakes are obvious when they are found and expensive when they are not. A range offset by one row will feed the right-looking number into the wrong place and no one is warned. The same patterns show up whether you are doing a quick WRC check, a head thickness, a nozzle reinforcement or a flange assessment.

Opacity compounds the problem. Spreadsheets make it easy to bury logic behind named ranges and helper tabs. That can be convenient for the author and frustrating for the reviewer who is accountable for the final sign-off. When a calculation cannot be audited quickly, the conservative response is to repeat it independently. Your submission is then treated as an attachment to rather than the basis for approval.

Why Code Tables and Graphs Are Hard to Automate by Hand

Pressure-vessel calculations depend on accepted methods. For nozzle-to-shell checks, WRC 537 and WRC 297 are used every day. The difficulty is not the mathematics; it is the mechanical work of interpreting limits, reading curves and applying the correct set of coefficients for the geometry at hand. When engineers translate those steps into spreadsheets, they recreate the method in fragments: a table entered here, an interpolation there, a chart image pasted as a reminder. Every recreation is a chance to mis-key a coefficient, reference the wrong region or step outside the method’s geometry limits without knowing. Excel can interpolate numbers; it cannot warn you that your d/D or T/t places the case outside the bulletin’s envelope unless you have built, tested and maintained that guardrail for every case.

When Excel Is Still Fine

There is nothing inherently unprofessional about Excel. For one-off scoping exercises, hand checks, early feasibility and simple tests, a small, well-annotated sheet can be more efficient than a full calculator. If you are exploring whether a concept is viable, the overhead of formal documentation can be counterproductive. Excel is also reasonable for stable, mature internal tools when they are tightly controlled, guarded by validation and used by a small, trained group.

The test is simple. If the calculation matters enough to be reviewed outside the author’s immediate team, and if it will be repeated, varied or reused, a spreadsheet starts to work against you. The more stakeholders involved, the more your tool needs to be standardised, self-validating and auditable. That is as true for a nozzle load case as it is for head sizing, reinforcement area or a flange capacity check.

What a Modern, Standardised Workflow Looks Like

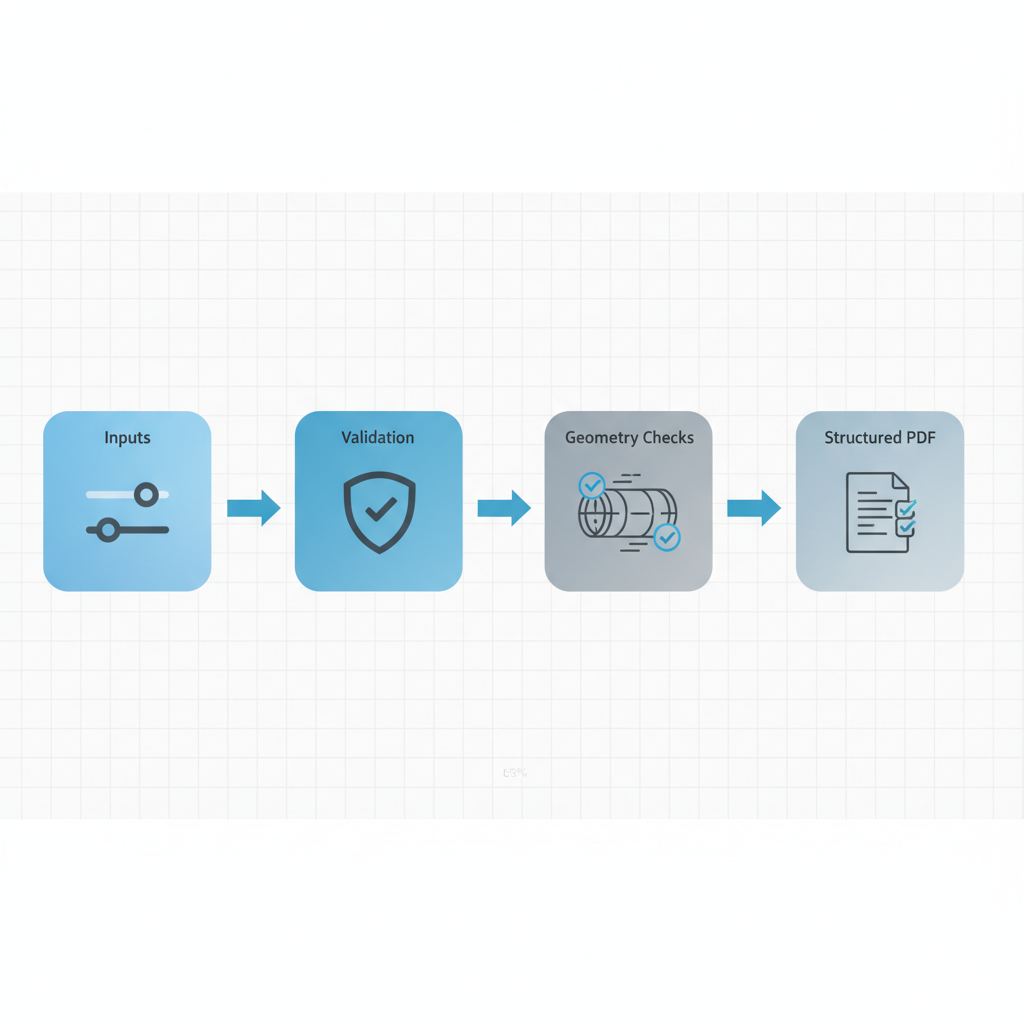

Context: structured inputs, automatic validation, geometry checks and a traceable PDF reduce rework and speed review.

A modern workflow does not eliminate engineering judgement; it protects it. The starting point is a purpose-built calculator that implements accepted methods and embeds the tables and curve-fit equations rather than asking the user to transcribe them. It checks geometry limits up front and reports when the method does not apply. It treats units explicitly, validates inputs as they are entered and makes assumptions visible. It records the calculation version, the Code edition and the user who ran it.

The outputs are structured and repeatable. Inputs, method and results are captured in a report that reads the way a reviewer thinks. The PDF references the calculator version and change log. If a change is made, regenerating the report creates a new entry that records what changed and when. Sharing is deliberate. A reviewer receives an authoritative record, not a forked spreadsheet they will inevitably edit. If a new load case is required, it can be created without breaking the original record.

Moving from Excel to PV Cloud Without Disruption

If you want to see the difference on real work, start with the WRC 107/297/537 nozzle calculator in PV Cloud, run your next case and compare the experience and the output to your current spreadsheet. You will spend less time wrestling, and more time doing engineering—and you will produce a report a reviewer can trust months from now when the job is revisited.

Use the nozzle calculator free here: https://pv-cloud.com

Closing

Pressure-vessel engineering will always require judgement. That judgement deserves a workflow that does not dilute it with transcription, version drift and audit gaps. PV Cloud makes the accepted methods easier to apply, the limits harder to miss and the results simpler to review. The outcome is not a shortcut around RPEQ sign-off; it is a higher-quality submission to it—delivered faster, with fewer surprises, and with a traceable record you can defend.